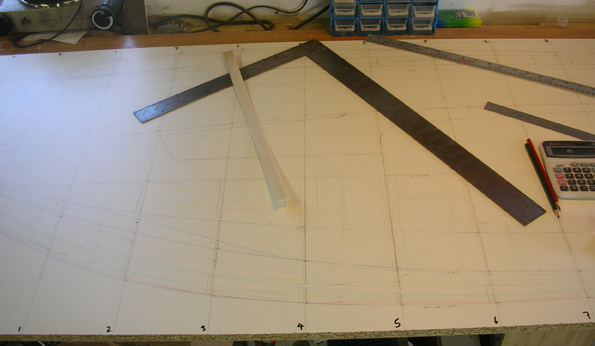

Photo by rick rowland via Flickr Creative Commons

Where lightweight and strength are needed wood is the best material to use.

Wood is stronger than than steel, most fiberglass and aluminium pound for pound.

Wood is stiffer than all fiberglass, kevlar and steel.

Wood absorbs vibrations and this includes sound, so wooden boats are quieter.

Wood does not fatigue with repeated loading,

Wood is a renewable resource and the growing of wood removes carbon dioxide from the atmosphere.

Wood is eco friendly in that it can be recycled, fiberglass cannot.

Wood looks good.

Wood allows economical, in both materials and cost, custom production of boats.

Wooden boats require similar maintenance to fiberglass boats. Gel coat is not the wonder material it was thought to be

So why are most boats for sale today made of fiberglass?

There is one reason most boats are built from fiberglass; that is cheap labour.

It requires skilled craftspeople to build a wooden boat, whereas semi-skilled and unskilled operatives with proper supervision can manufacture a fiberglass boat.

Fiberglass is not renewable and non-recyclable,

Fiberglass requires similar maintenance to a wooden boat. Gel coat is not the wonder material it was thought to be.

Update: 2-May-2010

I came across this article by Lawence W. Cheek in the Seattle Times today and he says exactly what I want to, but better.

“We willingly pour the considerable labor and love into building, maintaining and restoring wooden boats because they lead us to participating in something greater than ourselves. I have nothing against fiberglass, but a boat made of synthetic material simply reflects human culture back at us. It is purely a product of technology. A wooden boat is a partnership. It’s not literally a living thing, not quite, but it evinces respect for the life that exists outside the clubby circle of human intelligence.”

Photo by Botheredbybees via Flickr Creative Commons

Print or E-mail this post